When a dual extruder for 3D printing is available it is very desirable to be able to print using a support material that can be dissolved instead of mechanically having to remove it. I saw an interesting video describing a process that started this investigation. Here is the test result:

Continue reading

Category Archives: 3D Printer

Printer Heated Bed Design & Measurements

It is very desirable to have a heated build platform and unfortunately the Ultimaker does not have one. Therefore users have to improvise their own versions. Basically there are two common ways to provide the heat but as usual there are exceptions. Typically the heaters are used to heat a glass plate that acts as the built platform. The big advantage is that it is easy to get a flat glass plate and it can easily be cleaned off without worrying about damaging the original acrylic plate and tapes. Continue reading

Avoiding Nozzle Leaks

A common problem is plastic leaking around the nozzle. Different websites and Wikis suggest to use Teflon tape on the threads for sealing. That should not be needed if the parts are properly made. The Ultimaker nozzle and brass heater barrel that I received are very well-made.

There are only two locations that can leak: Each end of the brass barrel. Threads do not leak, that is a symptom of a failed seal at the barrel tip. Continue reading

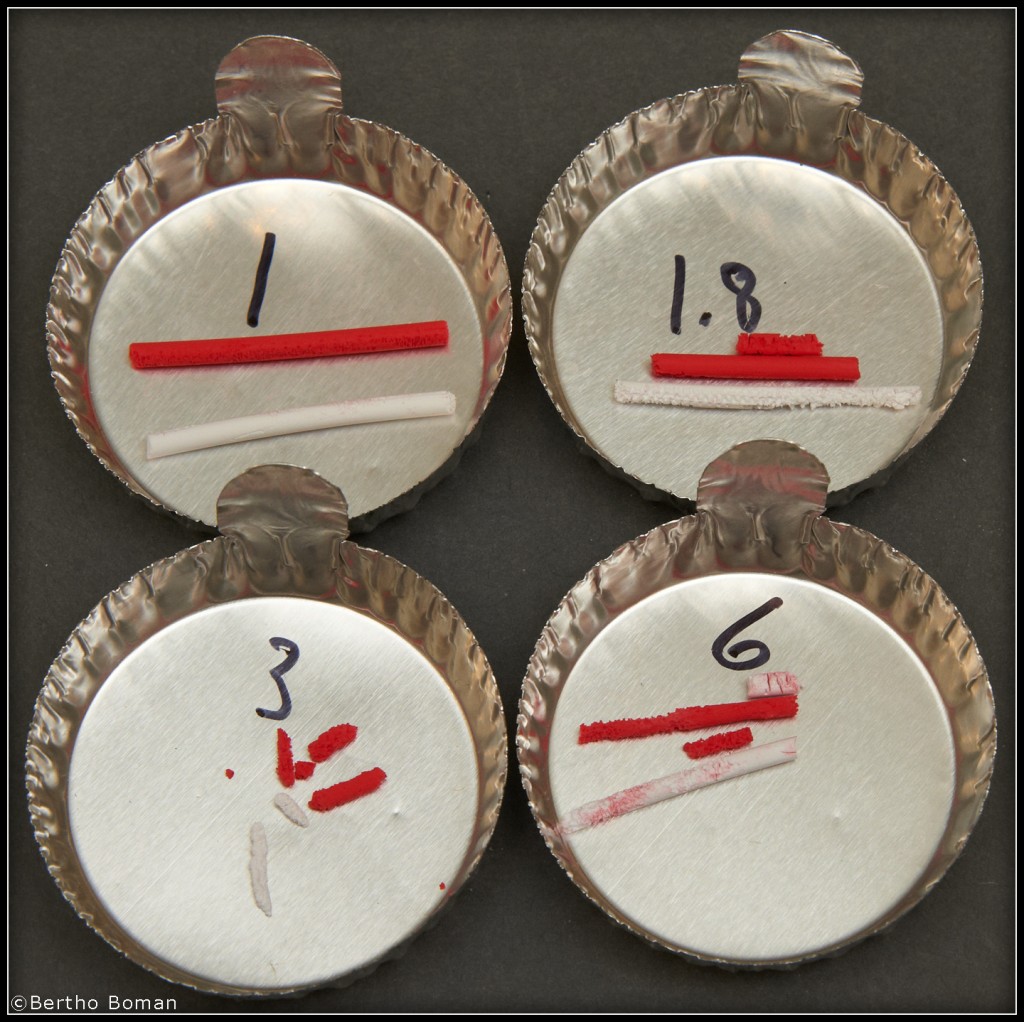

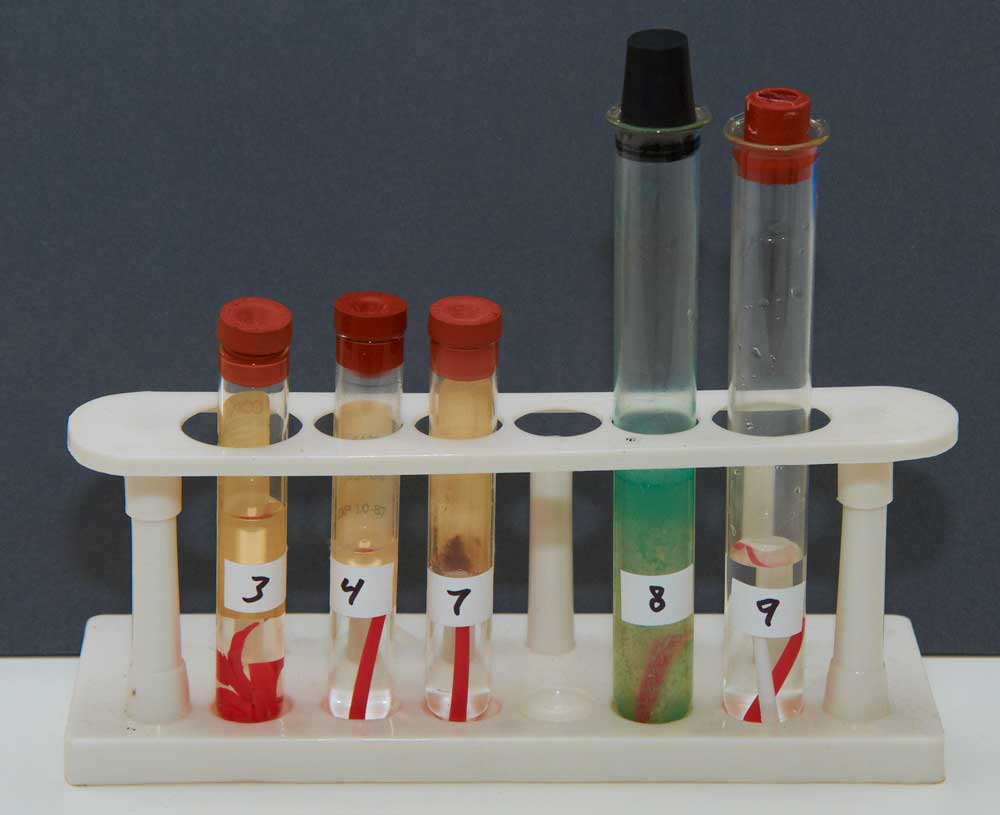

Dissolving PLA

PLA is a very common plastic used for 3D printing. I have been trying to find off-the-shelf products to dissolve PLA both for just cleaning it off hardware and for removing it if the PLA is used as support material.

My first goal is to find an easy way to remove PLA from nozzles, barrels and so on so they can be assembled cold without fighting with PLA residues. Please remember that we are considering two processes:

A: How to remove PLA from metal parts.

B: Dissolving PLA and leaving ABS untouched.

As for safety,should be reasonably safe when removing PLA by putting the small metal pieces in a glass jar with the chemical and cover with a lid and afterwards fishing out the pieces with tweezers or tongs .

When removing large amount of PLA support structures it will be much more critical to have a safe liquid since normally there will be relatively big objects to treat.

I tested: Continue reading

I tested: Continue reading

3D Probing

To duplicate an object it is sometimes necessary to accurately measure it. There are basically two directions to go: To measure point by point with a digital probe or other point measuring device or to use an optical scanner to obtain the desired information.

The digital probe requires a CNC system that is used to obtain point by point data measurements. When the highest accuracy is needed that is the way to go. Commercial probes are very expensive, many thousands of dollars. Here is a link to how to make your own and the software to convert the measured data.

The digital probe requires a CNC system that is used to obtain point by point data measurements. When the highest accuracy is needed that is the way to go. Commercial probes are very expensive, many thousands of dollars. Here is a link to how to make your own and the software to convert the measured data.

www.vinland.com/Touch-Probe.html

Extruder Drive Force Measurements

The next step in the quest for better performance and understanding of the printing process was to measure the actual drive performance vs. applied spring force. For the once interested, here is that link:

Spring Measurements

After the design of the Extruder Drive Upgrade in the previous entry, I needed a procedure to accurately measure springs since there were several questions in the user-groups about springs. Here is a link to the test procedure:

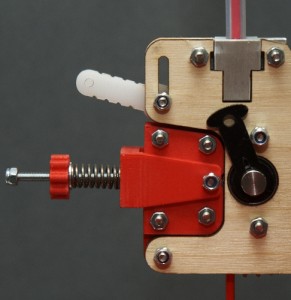

Extruder Drive Upgrade

The mechanism that feeds the filament into the extruder basically consists of a stepper motor that through a gear turns a knurled bolt. Th filament is pressed against the the knurled bolt and as the bolt turns the filament is forced into the Bowden tube. Although it works and many users do not have a problem I and many others have said many bad words about it. A search on user-groups and Thingiverse will show up multiple fixes and replacements for the drive. After analyzing the problems I came up with a good improvement that is easy to implement and the printer can even make the improved parts by itself. There are basically three problems:

1: The knurled drive bolt is marginal. Ultimaker recently upgraded it from V2 to V3 but I like to see an even better bolt with “proper” teeth cut instead of using a knurling tool.

2: The filament is pressed against the bolt by a stationary piece of plastic. Although it is made from Delrin there is unnecessary friction since the force pressing the filament is rather large.

3: The position of the pressing plastic is fixed so there is drastic variation in the pressing force for slight dimensional changes of the filament.

The solution that I came up with addresses the last two items and it makes a drastic improvement. Here is a link to the details:

http://www.vinland.com/UM_Extruder_Bearing.html

I also placed all the files on Thingiverse to make it easy for others to duplicate it:

Bowden Tube Fixes

The used filament is is driven by a stepper motor and fed through a rather stiff but flexible “Teflon” tube, called a Bowden tube, to the extruder section where the filament is melted and then dispensed as a very thin melted string. It is a clever idea since it reduces the mass at the moving “head” and allows faster acceleration. It also comes with drawbacks: The mounting method at both ends are not good and many users report problems because of that. Continue reading

Heated Build Platform “Bed”

The next item to change was the build platform. The standard one is an Acrylic plate covered by masking tape and I really dislike it. The bed adjustment screws also needed an improvement. There are two basic ways to add a heated bed:

1. Use low voltage high current heater. It is usually an etched pattern on a PCB and an external high current DC power supply.

2. Use a mains operated heater and no separate high current power supply is needed. Of course working with mains has additional risks but so does wiring a high current power supply that also needs to be connected to the mains.

I obtained a boro-silicate glass plate of the correct size and since I already had 120V heating pads that can be attached by a high temperature adhesive, I attached them to a matching size aluminum plate to evenly spread the heat since glass has poor heat conduction. I added a thermocouple sensor to the glass itself and the heaters are controlled by a commercial digital PID controller that I also happened to have.

After adding new mounting and leveling screws I am now very happy with that section.

Home Sensor & Limit Modifications

One of the first thing I did was adding a mechanical limit to the Z-stage. The X & Y motors with the belts are not strong enough to cause any damage if hitting the mechanical limits. I do worry about the Z axis causing damage since it has the screw pitch advantage for added force. For safety I added a clamp on the lead screw that

creates a safe limit if everything else fails. See Picture:

For accurate zeroing I added an opto-interrupter that is repeatable to a few microns, much better than the stability of the wood frame and table mounting.

See: http://www.vinland.com/Opto-Interrupter.html

See: http://www.vinland.com/Opto-Interrupter.html

I have the opto set so it triggers about a mm above the table so I never need to worry about hitting the table. I have in the software turned off the limit switches and only use them for homing.

Then in the startup code I have: G28 X0 Y0 ;move X/Y to min end stops G28 Z0 ;move Z to min end stops G92 X0 Y0 Z0.95 E0 ;reset software position to front/left/z=0.0

Tweaking the Z value will allow fine adjustment of the table without trying to fiddle with moving microswitches around.

3D Printer Startup

March-2012: I was too busy to start building the printer at once but once I started it was easy to put together since the kit is well-made.

The software and usage instruction were not so good but the user group support is great and I highly recommend to use the open source software for slicing and controlling the printer. The links are below.

Make sure to start with the excellent Cura to make the initial learning curve as easy as possible.

Personally I like full control so I do the slicing, scaling and preparation separately on my main desktop and then save the G-Code file on a server. Then I use the “Printrun” program on a dedicated small PC to run the printer.

Ultimaker forum and wiki: www.Ultimaker.com

Slicing software and Printrun: http://daid.github.com/Cura/

Google User group: ultimaker@googlegroups.com

Ordered a 3D Printer

20-Dec-2011: After spending a lot of time reading on different websites I finally decided on the Ultimaker kit. It was expensive, about $2,000 with the optional Netfabb software and shipping to the USA.