When a dual extruder for 3D printing is available it is very desirable to be able to print using a support material that can be dissolved instead of mechanically having to remove it. I saw an interesting video describing a process that started this investigation. Here is the test result:

Video:

3DSystems has a very useful video on YouTube about how to use caustic soda (Sodium Hydroxide NaOH) to dissolve PLA used for support. 217 grams is added to 3 liter water used at 60C for 3 hours in an ultrasonic cleaner. 217g in 3 liter is equal to 72.3g in 1 liter is equal 1.8 Molar strength.

http://www.youtube.com/watch?feature=player_embedded&v=uWYn5wJ72zY

The YouTube listed cost of the ultrasonic cleaner is ridiculously expensive. A few days ago I bought a similar but larger high-power 6l industrial ultrasonic cleaner for $279.

http://www.amazon.com/Commercial-Kendal-Liters-ULTRASONIC-CLEANER/dp/B002QD624C/ref=sr_1_2?ie=UTF8&qid=1346692474&sr=8-2&keywords=kendal+ultrasonic+cleaner

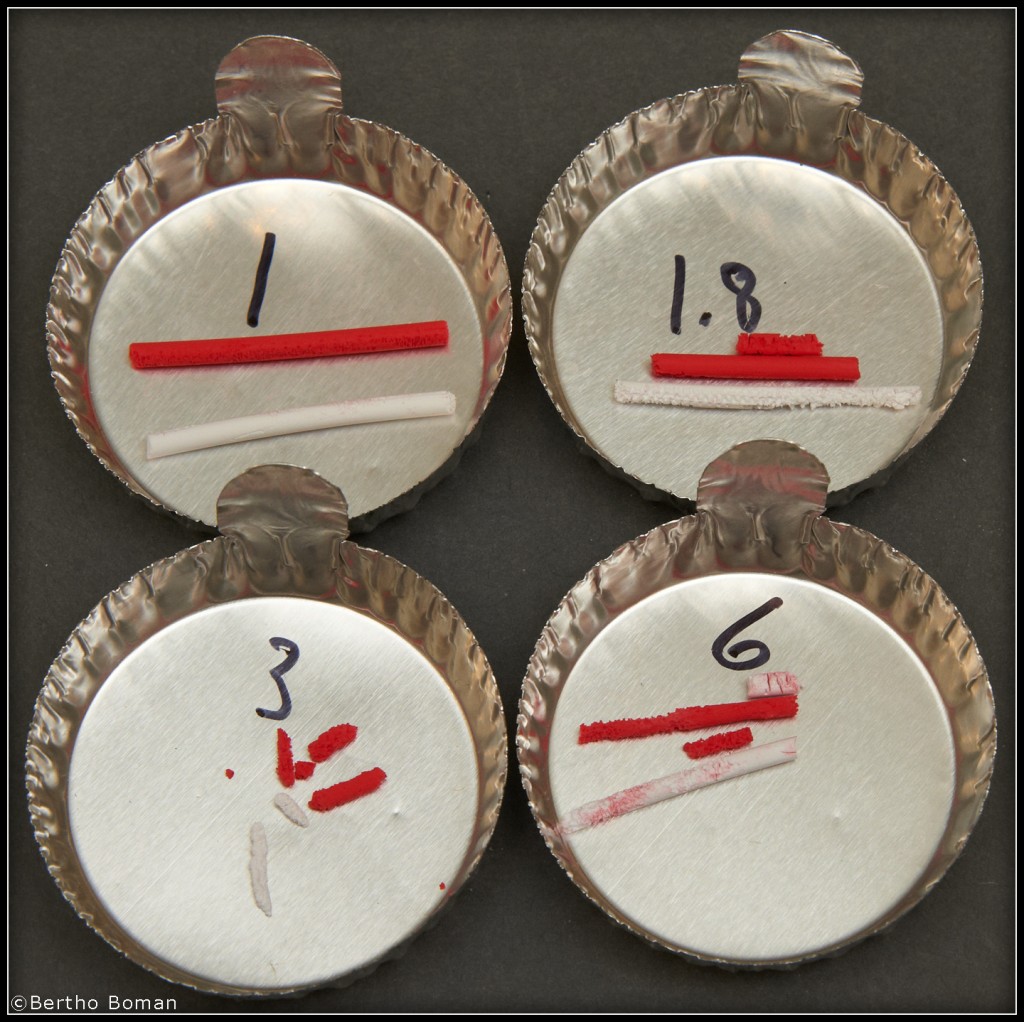

Samples before test

This time I tested several different plastic types and varying strength Sodium Hydroxide.

1.0 Molar: 40g per liter water

1.8 Molar: 72g per liter water (same as the video)

3 Molar: 120g per liter water

6 Molar: 240g per liter water

Plastic: Red and White 2.9mm filament samples of PLA and small samples of ABS, Polycarbonate (Lexan) and Nylon-66.

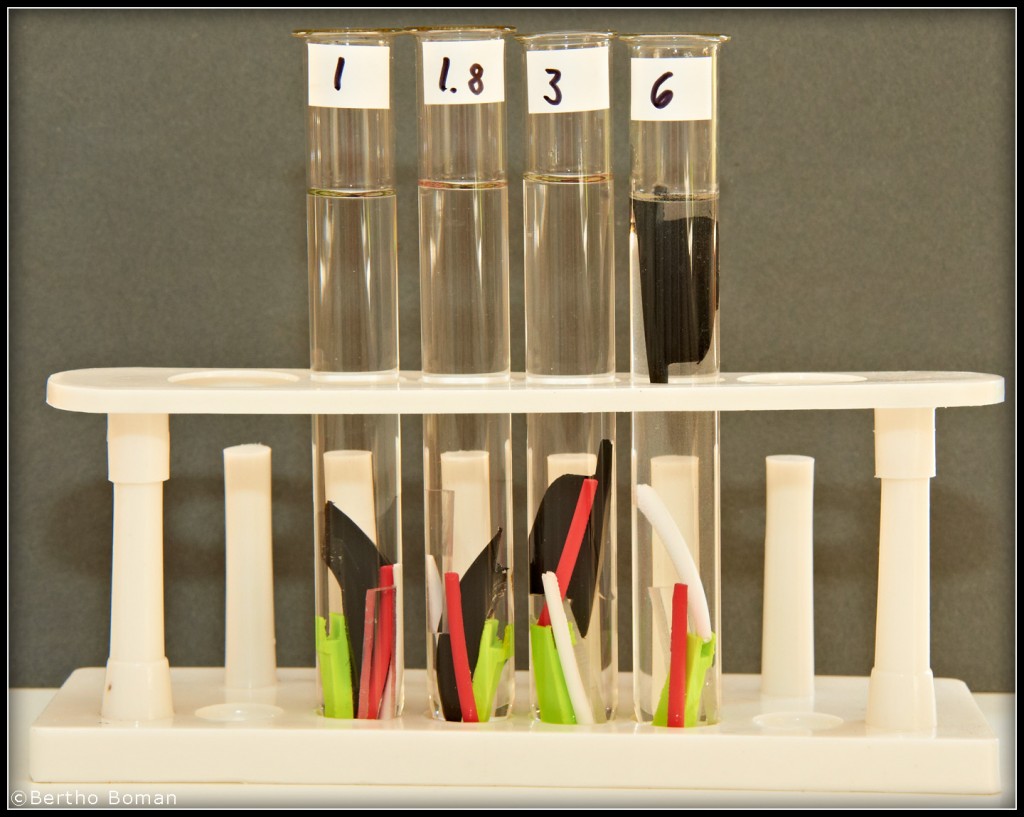

All the samples and the dissolving liquids were left in the test tubes and tested at the same time in the ultrasonic tank.

Test Result:

After 5 hours in the ultrasonic tank @ 60°C there was no visual effect or surface hardness change evaluating the samples under a microscope of the different plastic types except the PLA.

Amount of dissolved PLA after drying the residue (see top picture):

1 Molar: 13%

1.8 Molar: 42%

3 Molar: 88%

6 Molar: 56%

Five hours is much longer time than the video but dissolving thin scaffolding will be a lot faster than the solid 2.9mm filament so the estimate of three hours sounds reasonable. The big surprise was that the stronger mixture was worse so it looks like 3-4 Molar is a good value. A higher temperature would also further speed it up.

In summary it works and looks like a promising way to build scaffolding for 3D printing.

Here is a link to quickly dissolve PLA if no other plastic is involved:

http://www.vinland.com/blog/?p=68

I am in fact glad to read this weblog posts which carries plenty of useful data, thanks for providing such data.

Thank you.

Hey, that’s a clever way of thniinkg about it.

Thanks!

Just want to say your article is as surprising. The clarity in your post is just nice and i can assume you

are an expert on this subject. Fine with your permission allow me to grab your

RSS feed to keep up to date with forthcoming post. Thanks a million and please carry on the

gratifying work.

Thank you. You are very welcome to RSS. I will try to add more information when I have some spare time.