PLA is a very common plastic used for 3D printing. I have been trying to find off-the-shelf products to dissolve PLA both for just cleaning it off hardware and for removing it if the PLA is used as support material.

My first goal is to find an easy way to remove PLA from nozzles, barrels and so on so they can be assembled cold without fighting with PLA residues. Please remember that we are considering two processes:

A: How to remove PLA from metal parts.

B: Dissolving PLA and leaving ABS untouched.

As for safety,should be reasonably safe when removing PLA by putting the small metal pieces in a glass jar with the chemical and cover with a lid and afterwards fishing out the pieces with tweezers or tongs .

When removing large amount of PLA support structures it will be much more critical to have a safe liquid since normally there will be relatively big objects to treat.

- Boiling water for about 10 minutes then soaking for 24 hours: No obvious change.

- Denatured alcohol soaking for 24 hours: No obvious change.

- Acetone soaking for 24 hours: The PLA swelled up and has a rubbery feel and it split apart into several pieces. The splitting happened after a couple of hours. It was not dissolved (clear liquid).

- MEK= Methyl Ethyl Ketone soaking for 24 hours: Slight swelling, a rubbery feel and partial split length wise. It was not dissolved (clear liquid).

- TriChloroEthane soaking for 24 hours: Slight swelling, a rubbery feel and partial split length wise. It was not dissolved (clear liquid).

- PVC cleaner: Oatley #30782 soaking for 24 hours: Slight swelling, a rubbery feel and partial split length wise. It was not dissolved (clear liquid).

- Weld-On #5: It is a solvent for extruded Acrylic made by IPS corporation. It completely dissolved the PLA in a couple of hours and I ended up with a red liquid. (My PLA sample was red). More Weld-on notes below.

- Miller-Stephenson’s MS-111 Stripping Agent. It dissolved the PLA in an hour or two. That chemical is very nasty, it will even dissolve cured epoxy. It was only allowed to be shipped by ground and it was packaged like those Russian dolls inside each other: I think there were 6 boxes inside each other with padding in-between. One intermediate container was a metal can and inside it another box and finally the glass bottle.

- Draino Crystals. It is a lye-based drain cleaner. No effect after 12 hours.

- Kleen Strip premium sprayable stripper: It is a paint remover containing Methylene Chloride. It is listed as sprayable and comes with a sprayer but is still like a sticky paint remover but thinner. It dissolved the PLA in a couple of hours but is messy and sticky and leaves a residue that has to be scrubbed off.

I bought the Weld-on #5 solvent several years ago and today I am having trouble finding it. On internet I see a #5 cement but that is presumably a thick version and not suitable. Here is a link to what I have: http://www.coloradoplastics.com/wholesale/products/ips-weld-on-adhesives/ips-weld-on-5/

The Weld-on #5 has been discontinued and I have to find and test the replacement. Weld-on recommended #4 but I have not tested it. Here are some details:

Weld-on #5 contains: Methylene Chloride(75-09-02), Glacial Acetic Acid (64-19-7), Methyl Methacrylate Monomer (80-62-6)

Weld-on #4 contains: Methylene Chloride(75-09-02), Methyl Acetate (79-20-9), Methyl Methacrylate Monomer (80-62-6)

I have no idea if the difference is significant, all I know is that #5 works extremely well.

Here is an link to a commercial product in Germany:

http://ifeelbeta.de/index.php/component/content/frontpage

3DSystems has a very useful video on Youtube about how to use caustic soda (Sodium Hydroxide) to dissolve PLA used for support. 217 grams is added to 3 liter water used at 60C for 3 hours in an ultrasonic cleaner. 217g in 3 liter is equal to 72.3g in 1 liter equal 1.8 Molar strength.

http://www.youtube.com/watch?feature=player_embedded&v=uWYn5wJ72zY

The listed cost of the ultrasonic is ridiculous pricing. A few days ago I bought a high-power 6l industrial ultrasonic cleaner for $279.

My old one died after about 20 years of service. As soon as it arrives I will of course test it for PLA removal.

The Ultrasonic cleaner arrived, more testing:

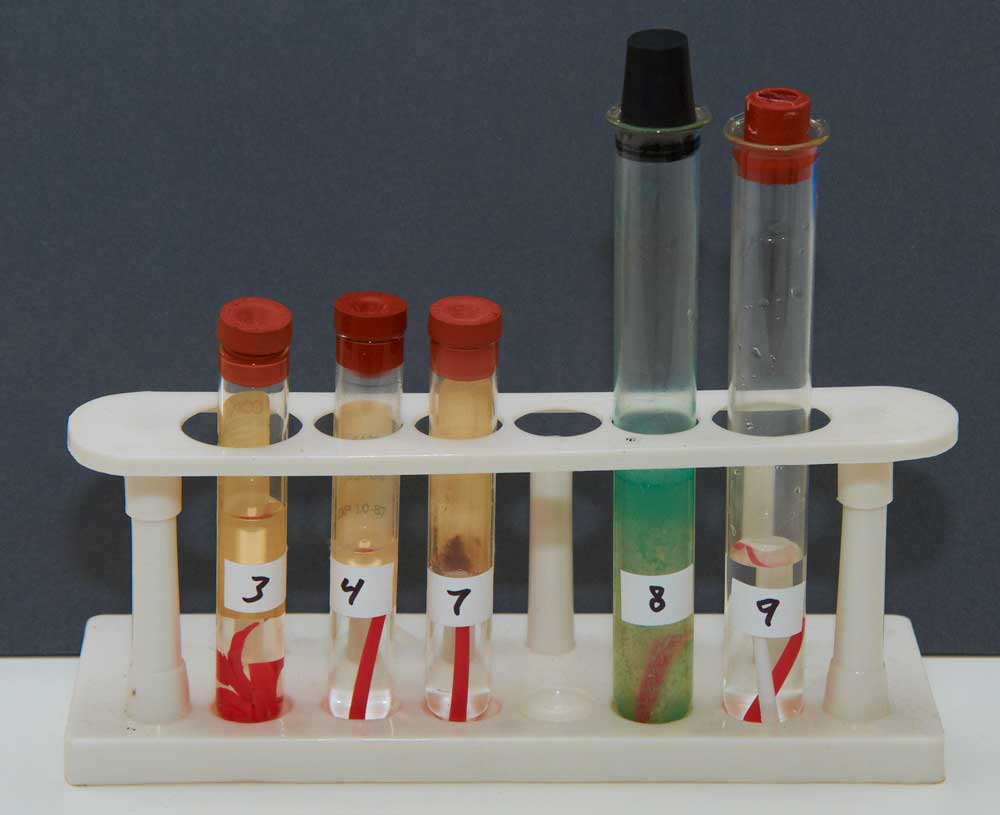

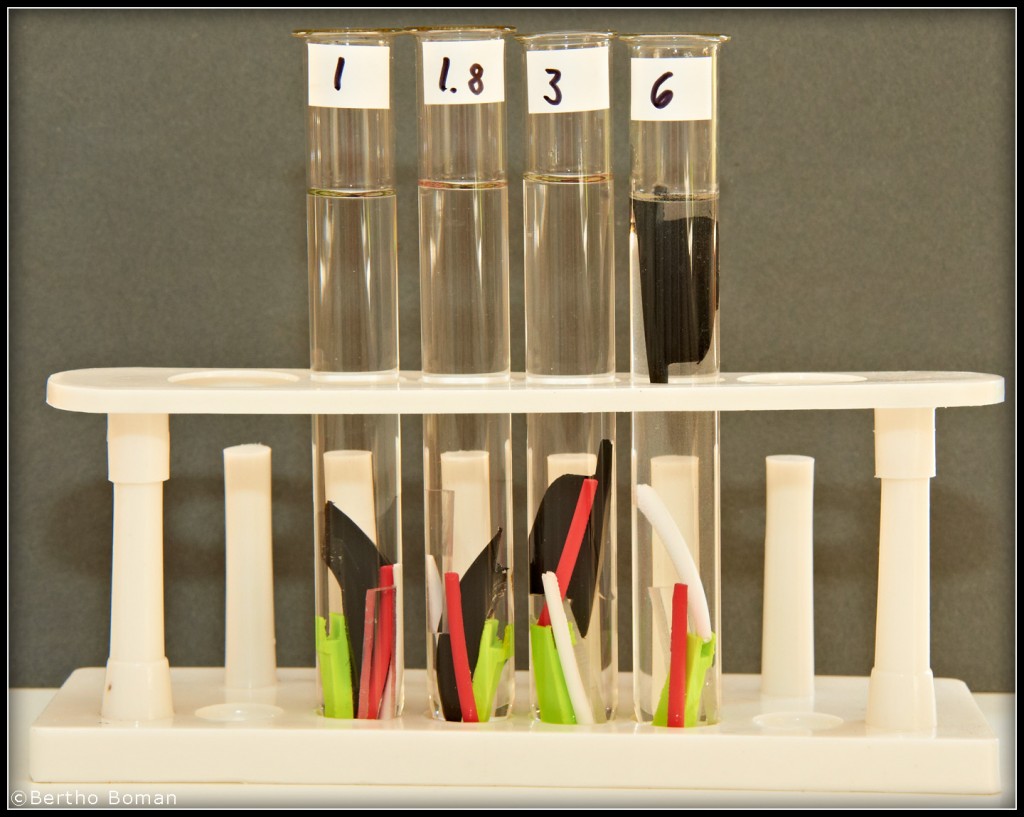

This time I tested several different plastic types and varying strength Sodium Hydroxide.

1.0 Molar: 40g per liter water

1.8 Molar: 72g per liter water (same as the video)

3 Molar: 120g per liter water

6 Molar: 240g per liter water

Plastic: Red and White samples of PLA, ABS, Polycarbonate (Lexan) and Nylon-66

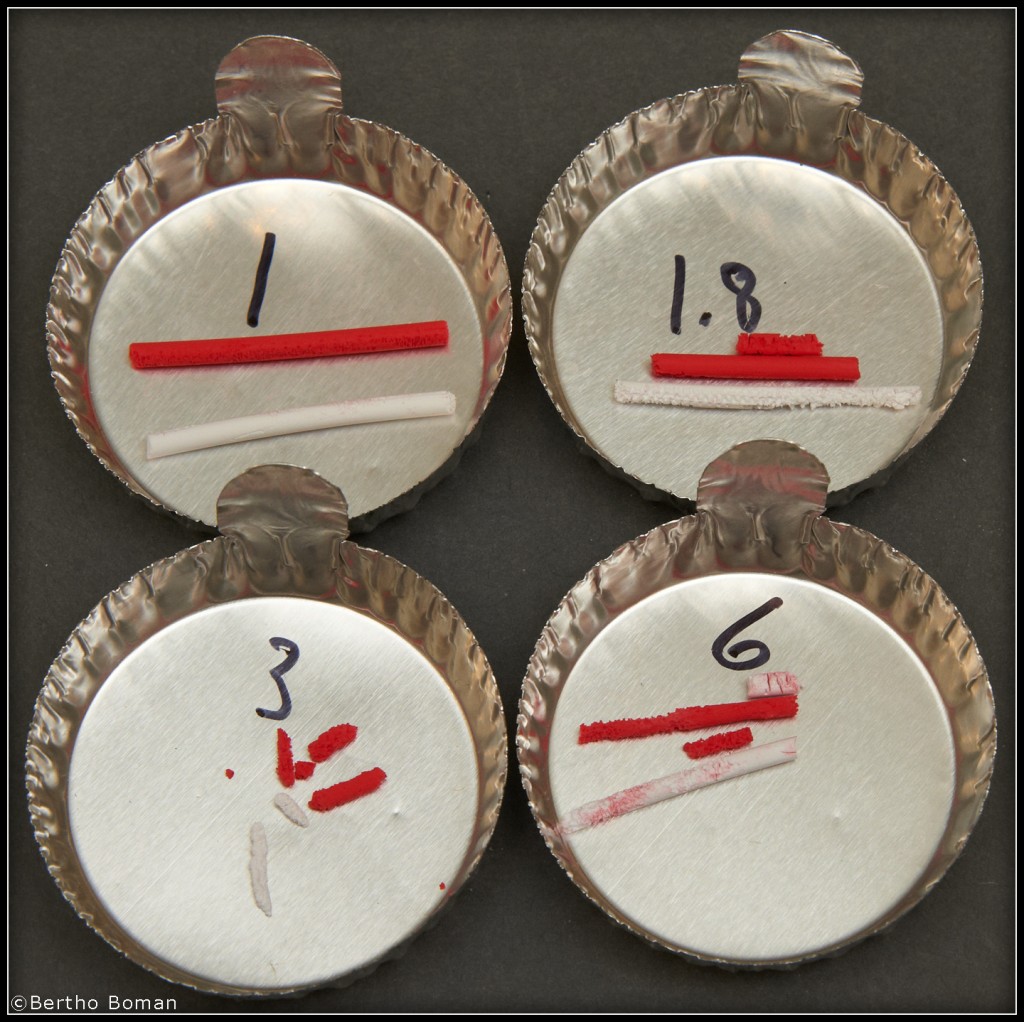

After 5 hours in the ultrasonic tank @ 60°C there was no visual effect on the different plastics except the PLA. Amount of dissolved PLA after drying the residue:

1 Molar: 13%

1.8 Molar: 42%

3 Molar: 88%

6 Molar: 56%

Five hours is much longer time than the video but dissolving thin scaffolding will be a lot faster than the solid 2.9mm filament so the estimate of three hours sounds reasonable. The big surprise was that the stronger mixture was worse so it looks like 3-4 Molar is a good value.

One note- the red color in some of the solutions is not a sign you are dissolving PLA, just that you are mobilizing some amount of the dye. Absent some physical change to the plastic I would not assume it was affected simply because the solution turned a different color. Use clear filament of a measured dry weight and measure again after drying.

The PLA definitely was dissolved, both the red and the white one. See the residue in the measuring cups picture. It was measured before and after wards dried. That is how I calculated the %.

Really nice investigative blog.

when I dissolve the Stratasys support material (not PLA) , I get the water near a hard boil.

I use about 2 tablespoons per 15 ozs, although it is not consistent.

I put it in a jar and stir it manually several times in a 20 minute period.

Then I pour it out and boil up some more water and repeat about 2 or 3 times.

I also break off all that I can before, so only the inaccessible support is left.

You might try your temps at about 190F/90C or so. A prototype house gave me that target temp.

Dave

Thanks Dave,

2 tblsp in 15oz H2O is about 140g/l = 3.5 Molar strength so that closely matches my best strength.

I of course expect to break off what can easily be done and I will keep in mind to test at higher temperature too.

Bertho

Bertho? You don’t happen to have some of that soft PLA in your house? I have a feeling it would dissolve much easier?

J

The white PLA was the over-sized PLA that I received from UM.

Pingback: Dissolving PLA used as support for ABS | Vinland Blog

Have you tried rf to dissolve the pla?

What do you mean by “rf”?

PLA plastics can be dissolved in dichloroethane. I use it to process models of PLA

Weld-On #4 works quite well. I just used it to clear up a thoroughly jammed nozzle.

Mind you, both Weld-On products are rather dangerous…I would use them for problems like mine but don’t think I’d want to be doing it on a regular basis to remove support structures.

Did you use Weld on #4 for PLA or ABS plastic. I see in the documentation that it works well for welding ABS but it does not mention PLA.

I have only been using it to dissolve PLA.

THF, done. Stop doing these experiments and buy a soluble support…

Weld on #4 should work just as well (but not sure).

The component that dissolves the PLA (and can also dissolve ABS, but not the nylons I have tried) is methylene chloride, AKA dichloromethane.

silly question: has anyone tried dissolving natural PLA in dishwasher tablet solution + ultrasonic?

have you tried using LIQUID SOLVENT CEMENT? http://modelshop.co.uk/Shop/Adhesives/Methane-Based-Adhesives/Item/Liquid-solvent-cement-500ml/ITM5061

This solved my clogged nozzle problem and it dissolved the PLA in an hour.

I have not tried that brand but it looks similar to the once that I tried.

You should give it a try, i mean it’s worth a try.

Can you put a note somewhere near the end that says:

“This is what dissolves PLA: ”

and fill in the last part with something that dissolves PLA.

Thanks.

Bertho

We are just entering the 3D printing world (printing models for educational purposes in our veterinary school) and ran across your post. Looks like you may have saved us $1000. Are you still happy with your results?

Thanks for your work and willingness to share.

Hi Jim,

Yes, I am very happy. My only regret is that I did not get rid of the PLA earlier and switch to ABS.

It can be sanded, machined and acetone vapor polished with great result.

Ethyl acetate? You can buy it on amazon in the UK.

Ive not had any luck with Ethyl Acetate.

Ive soaked it for weeks,

Powered the PLA and soaked. It did not dissolve.

The natural solvent of PLA is THF (Tetrahydrofuran). It’s a toxic material, but not so dangerous – more or less at the same level as Acetone. It’s possible to purchase I guess.

THF is also common as a solvent for PVC foils used in swimming pools. You can get it in pool equipment stores.

See the August 25th entry for details on testing many solvents, including THF.

I’m afraid there’s no such entry. The only place where THF is mentioned is on these comments.

This person is what real science is science about!

Thank you for putting in the time to make this thorough and to include what failed and where. The pictures. The numbers.

I am so happy to find this. I really thank you!

I will keep on the search for the holy PLA dissolver!

Thanks Casey!

Weld-on 4 works quite well. It is now called SCIGRIP Weld-on 4.

We’ll I hope I’m thinking in the right direction here. I’m doing research on the best solution to remove plastic type vinyl wraps off of a fleet of trucks. So I have vinyl wraps on about 10 50 foot tractor trailers and I need to find a solution to remove the vinyl and air egress adhesive with 1 application of chemicals. After reading this I’m wondering if the mixture of Methylene Chloride, Glacial Acetic Acid, Methyl Methacrylate Monomer would lift the wrap without harming the paint finish??

Or does anyone have a suggestion on what might work for this application.

Will the THF-Tetrahydrofuran by itself lift the wrap and adhesive?

Will the Ethyl acetate lift the products off the surface??

Please help if you can.

Thanks

D

I do not have an answer for you but hopefully some other reader might be able to help.

Of course careful testing on a hidden spot is critical.

Methylene chloride (dichloromethane) is paint stripper. It will destroy the paint.

PLA is polyester and as such is not very soluble. Solubility is also dependent on molecular weight. During extrusion process PLA degrades a bit. Very good info on PLA could be found here: http://onlinelibrary.wiley.com/doi/10.1111/j.1541-4337.2010.00126.x/full

Any acids will dissolve PLA (hydrolize). Glacial Acetic Acid, Oleum, etc., but is is not a dissolution, it is more decomposition. Polimer degrades to oligomers and monomers.

THF is probably the only organic solvent which dissolve PLA slightly. I can assume that dioxane will dissolve it also

Lucky I found this, thanks!

Hi there, just wanted tο say, I liked this article.

It was practical. Keep on posting!

Another commercial product that might be worth a try is Weld-On P-70 which is a primer for PVC/CPVC plumbing. The major ingredient is Tetrahydrofuran (45-59%).

http://weldon.com/primers-cleaners/p-70/

http://weldon.com/wp-content/uploads/2015/09/W-OP68LoVoc-4-15.pdf

THF is a great solvent, but very toxic. Use products containing it with a lot of ventilation. It goes through most gloves almost instantly. Nitrile and Vinyl gloves are worthless. There are 10 mil polybutylalchohol gloves that work, but they are disposable and cost 40 dollars a pair. (That’s right, a pair!) Neoprene gloves work minimally. Double glove (one glove over another) and change the glove immediately if you get any on it.

Another poster mentioned dichloromethane. That’s the same thing as methylene chloride. Those are also very toxic. Nitrile gloves work OK for methylene chloride, but again, change them immediately if you spill any. Methylene chloride (like most chlorinated solvents) causes liver damage)

Thank you for very good an important feedback.

I am really loving the theme/design of your web site. Do you ever run into any browser compatibility problems? A few of my blog readers have complained about my website not working correctly in Explorer but looks great in Chrome. Do you have any tips to help fix this issue?

Use Paint stripper for PLA (soak for a few hours) if you need to remove from hard to reach hotend parts and acetone to dissolve ABS

Very informative article post.Really looking forward to read more. Fantastic. aceddddffdeg

I like this site because so much useful stuff on here : D.

You’re so awesome! I don’t believe I’ve read something like

this before. So great to discover someone with a few unique thoughts on this issue.

Really.. thank you for starting this up. This web site is one thing that’s needed on the internet, someone with a bit of originality!